REVIEW

SA JOURNAL OF DIABETES & VASCULAR DISEASE

22

VOLUME 8 NUMBER 1 • MARCH 2011

Insulin devices: an added complexity

For biosimilar insulins, the additional dimension of the

administration device should also be considered. Stringent

regulatory requirements for insulin administration devices specify

use of durable labels and distinguishing marks, visibility of the

dose and accuracy with which it is dispensed after storage and

handling under a variety of environmental conditions, including

having been physically dropped. For example, cartridges, syringe/

needle systems, disposable and reusable pens and pumps must be

tested with each insulin formulation and concentrations that will

be used. Since the combinations of insulin and device may differ

widely in their dosing characteristics, it cannot be assumed that an

insulin biosimilar will be compatible with an existing administration

device. For this reason the EMA requires that compatibility is

demonstrated.

23,24

Insulin pen injectors and cartridges (3.0 ml

cartridge in the U-100 strength is the current market standard)

provide more accurate and reproducible dosing than syringes and

vials. They are also more convenient, easier to transport and may

improve safety and adherence,

25–27

suggesting that the availability

of pen injectors should be a requirement for insulin biosimilars.

Regulatory requirements for insulin biosimilars

In recent years the EMA has produced an overarching guideline

on biosimilars

28,29

as well as guidance documents addressing quality

issues,

30

non-clinical and clinical issues,

31

and guidelines for specific

biosimilars, including soluble recombinant human insulin.

21

As mentioned earlier

9

the EMA requires that biopharmaceuticals

undergo comprehensive comparability studies of both the drug

substance and product to provide evidence that the biosimilar is

indeed similar in quality, safety and efficacy to a single appropriately

chosen reference product that has the same pharmaceutical form,

strength and route of administration that is already approved

in the EU. In general, required preclinical data include primary

pharmacology and repeat-dose toxicology data. The EMA requires

that maintain isotonicity (to minimise injection pain and tissue

damage).

22

Any variations in the entire process of insulin synthesis and

formulation may result in a product which may be physicochemically

very similar to an appropriate reference product, but which differs

subtly in its clinical PK or PD characteristics.

9,14

The steps in the

manufacture of insulin are summarised in Fig. 6.

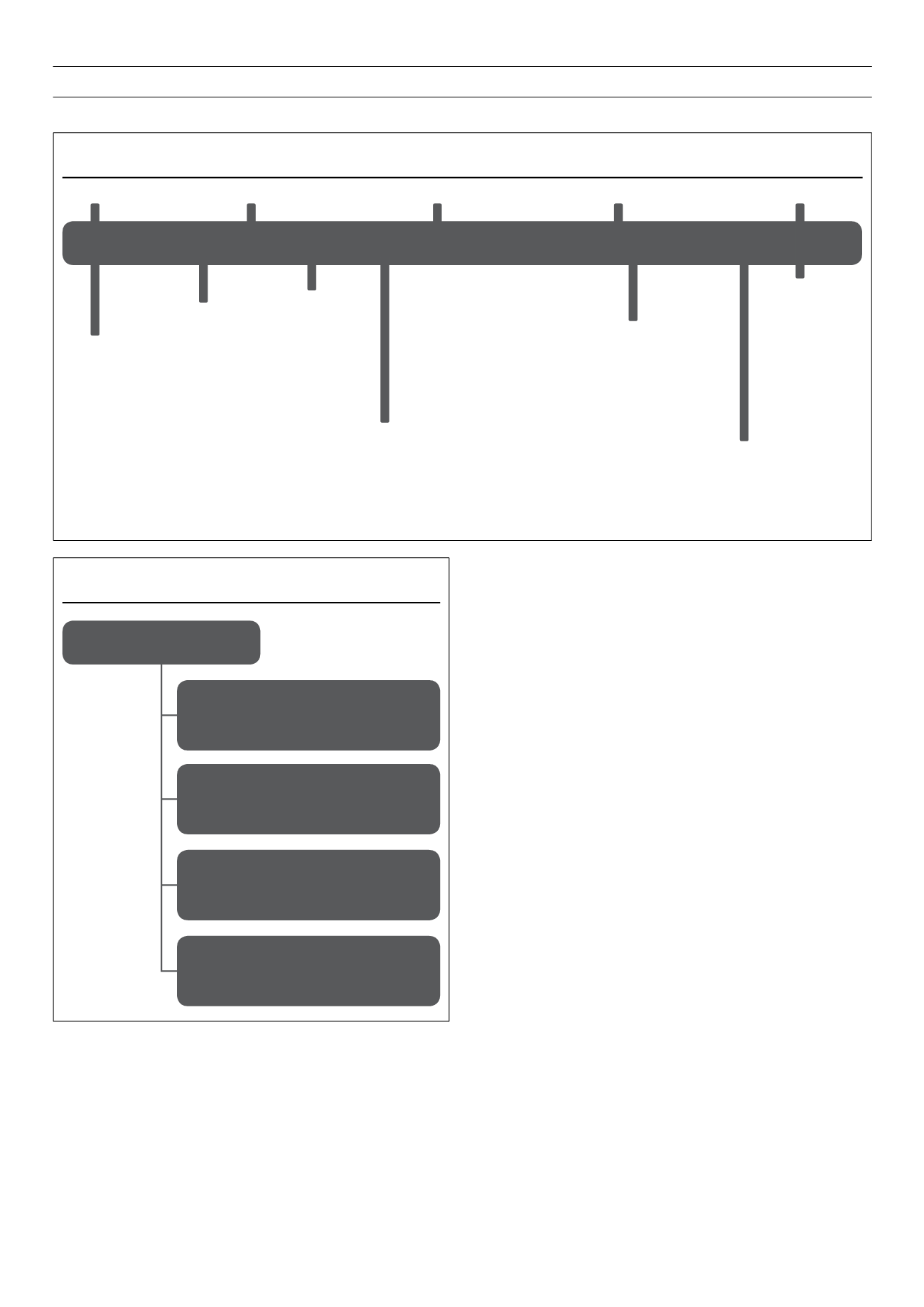

Figure 5.

Insulin medicinal products currently available: a summary.

Insulin medicinal products

Rapid-acting insulin formulations

Insulin analogues: insulin aspart, insulin

glulisine, insulin lispro monomers, clear

solution

Regular-acting insulin formulations

Zn- and preservatives containing insulin

hexamers clear solution

Intermediate-acting insulin formulations

Insulin or insulin analogue isophane

suspension (Cocrystallised insulin and

protramine) turbid or cloudy suspension

Long-acting insulin formulations

Ultralente insulin-Zn-crystals: turbid

suspension insulin analogues; insulin glragine,

insulin determir clear solution

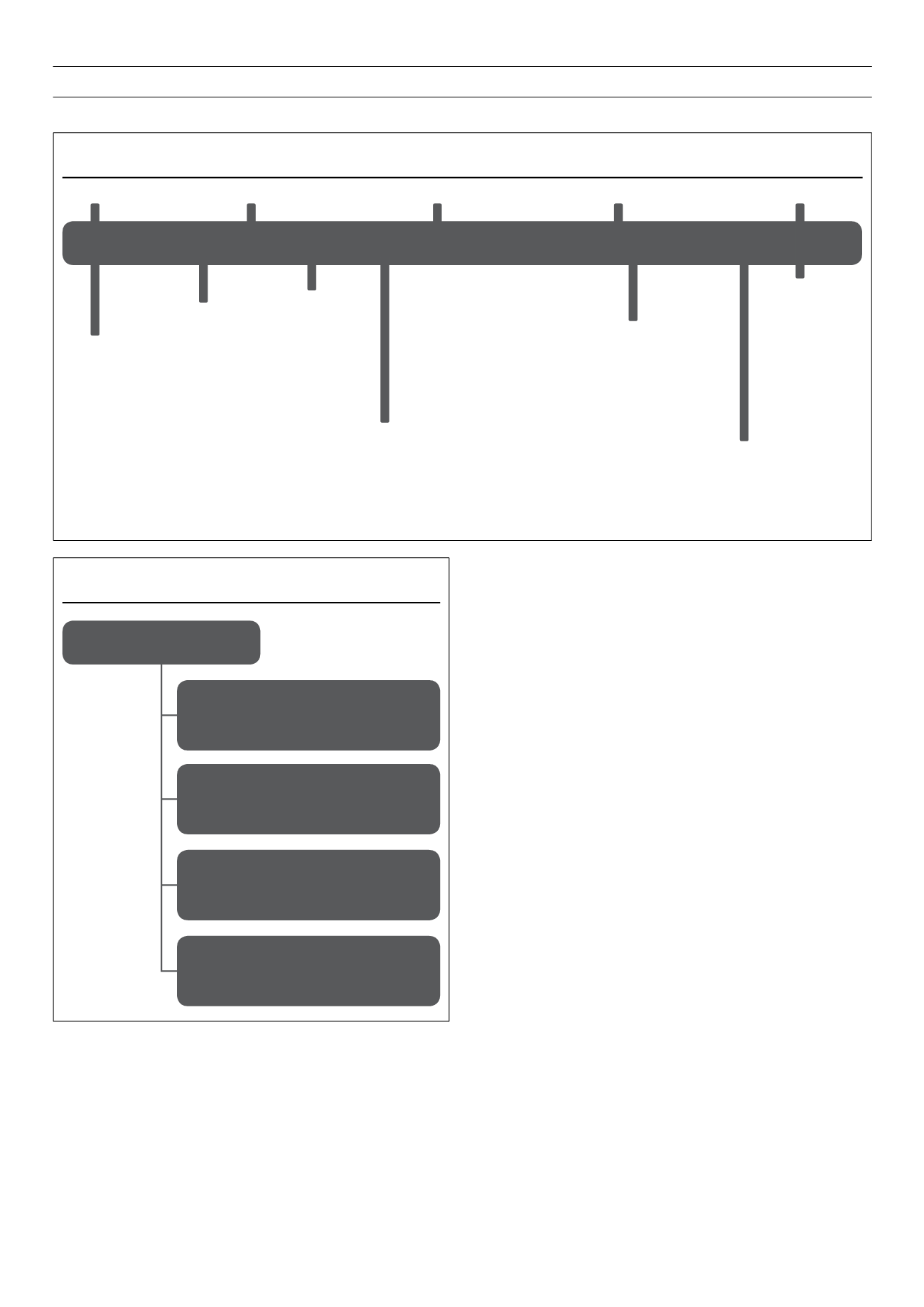

Figure 4.

The development of therapeutic insulin: a timeline.

14–16

Since the discovery of native insulin in 1921, successive discoveries have improved the production of therapeutic insulins as well as their pharmacokinetic and

pharmacodynamic properties. Work on therapeutic insulins has garnered three Nobel Prizes.

NPH

=

neutral protamine Hagedorn; PZI

=

protamine zinc insulin.

Insulin

discovered

PZI

NPH

insulin

Lente

insulins

Human

insulin

Rapid-acting

analogue

Long-acting

analogue

1921

1940

1960

1980

2000

Nobel Prize

1923

Nobel Prize

1958

Nobel Prize

1977