SA JOURNAL OF DIABETES & VASCULAR DISEASE

REVIEW

VOLUME 8 NUMBER 1 • MARCH 2011

21

or substituted amino acid residues. The first short-acting analogues,

insulin lispro and insulin aspart, were introduced in the late 1990s,

and the first long-acting analogue insulin glargine in 2000. Each

of these innovations was made with a view to improved onset and

duration of action,

14–16

to reduce hypoglycaemia and hyperglycaemia

and to improve tolerability. The history of developments in insulin

is summarised in Fig. 4 and a summary of available insulins is given

in Fig. 5.

In the manufacture of recombinant human insulin, the

recombinant organism that actually expresses the precursor protein

is generally

Escherichia coli

or a yeast such as

Saccharomyces

cerevisiae

. The engineered gene encoding for the precursor protein

must be inserted into a suitable stable expression vector. The choice

and the characteristics of this construct will affect key aspects, such

as the degradation characteristics of soluble proteins and the yield

of the process. The recombinant cells are screened, and a well

characterised master cell bank is established from a single clone.

This master cell bank is used to create uniform working cell banks

that are used to cultivate the cells and produce the desired product.

During product synthesis the culture and fermentation conditions

are tightly controlled in order to optimise yields and avoid formation

of unwanted by-products.

17

Generally, impurities come from either

the growth medium (especially for products isolated from cell

culture supernatant) or the host cells. These impurities can be host-

related (e.g. endotoxins, HCPs, DNA, viruses), product-related (e.g.

denatured protein, aggregates, protein fragments, deamidated

species, conformational isomers), or process-related (e.g. growth

medium components, metals, column material). When the product

is recovered, modified and purified the formation of inclusion

bodies (for example in high-yield

E. coli

processes), requires the

disruption of the cells to release preproinsulin. This is then isolated,

purified and folded, and then enzymatically cleaved to produce the

mature insulin molecule.

18–20

In the case of insulin, impurities such

as desamido forms may arise as by-products of conversion from

proinsulin to insulin by removal of the C-peptide and regeneration

of the three-dimensional form of the molecule.

21

After numerous purification steps, the insulin is crystallised

or lyophilised and formulated. The insulin molecule is negatively

charged at neutral pH, and readily associates into dimeric complexes

or into zinc-containing hexamers (Fig. 2). Thus, zinc may be added

to trigger aggregation into soluble discrete hexameric structures

containing two zinc ions per hexamer.

14

Phenolic excipients, added

as antimicrobial agents, also bind to specific sites on hexameric

insulin, changing its conformation to a more stable form (so-called

T–R transition). Other agents added at the formulation stage

may include physiological buffers (to maintain pH) and agents

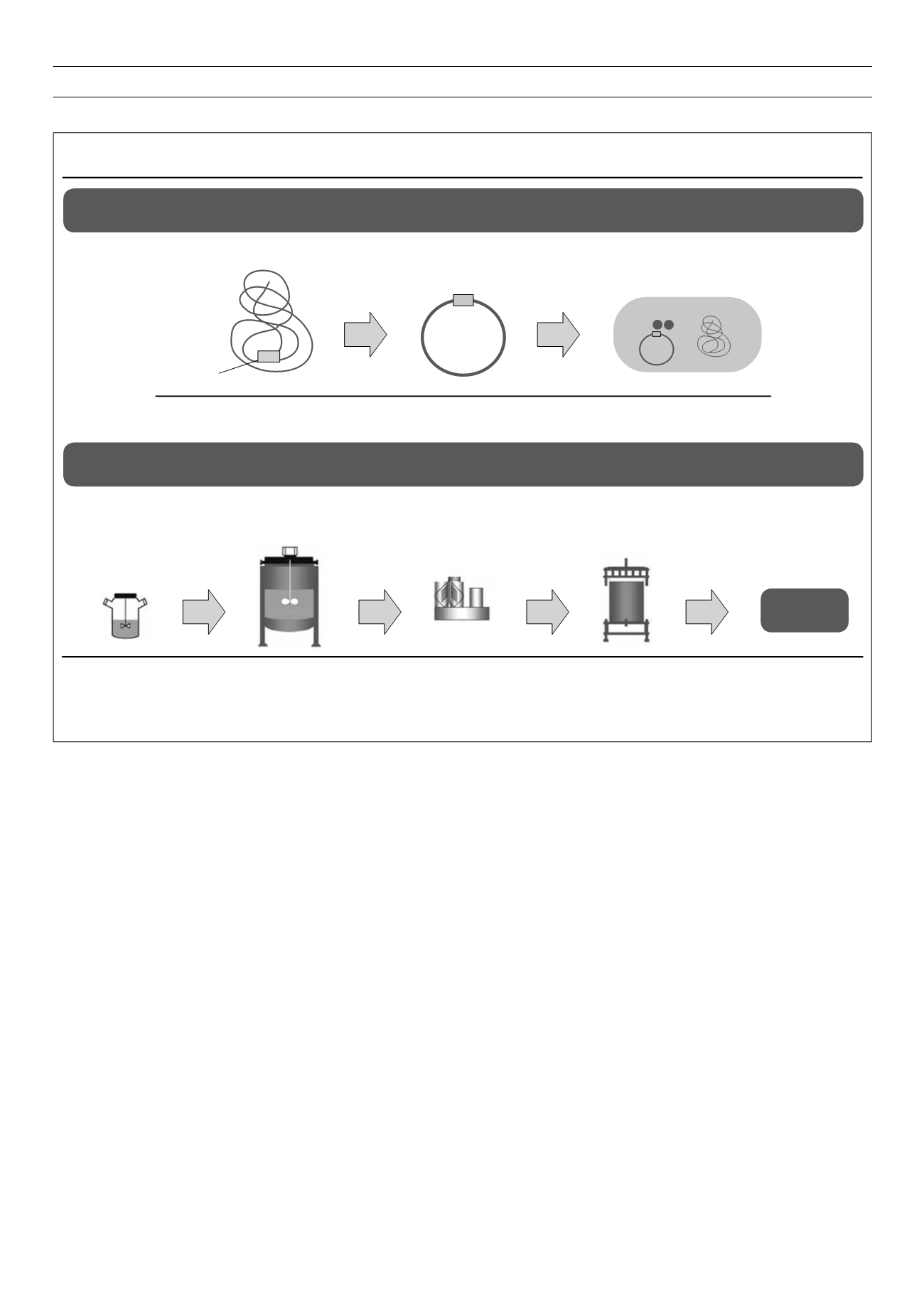

Figure 3.

Manufacture of a biopharmaceutical: opportunities for variation between manufacturers.

11

Adapted from Mellstedt H,

et al

.

Ann Oncol

2008;

19

: 411–9.

11

Cloning and protein expression

Cloning into DNA vector

Transfer into host cell

expression screening/selection

Source

DNA

Target DNA

Possibly same

gene sequence

Probably

different vector

Different cell

expression system

Protein production, purification and validation

Cell

expansion

Cell production

in bioreactors

Recovery through

filtration or

centrifugation

Purification through

chromatography

Characterisation

and stability

Different cell line,

growth media,

method of expansion

Different cell line,

growth media,

bioreaction conditions

Different

operating

conditions

Different binding

and elution

conditions

Different methods,

reagents, reference

standards

Purified

bulk drug