SA JOURNAL OF DIABETES & VASCULAR DISEASE

REVIEW

VOLUME 8 NUMBER 1 • MARCH 2011

23

toxicological studies that focus on potential immunogenicity,

as well as

in-vitro

affinity bioassays, assays for insulin and IGF-1

receptor binding, and tests for intrinsic activity.

28–31

One of the main concerns when switching or substituting

insulin products is hypoglycaemia caused by differences in activity

of different brands. Therefore, it is obligatory to ensure that the

effects of any insulin product in clinical use are highly consistent

and predictable. The EMA requires at least one PK single-dose

crossover study that compares the biosimilar insulin with the

reference product, using subcutaneous administration, preferably

in patients with type 1 diabetes. Clinical activity must be determined

in a comparative PD study, designed as a double-blind, crossover,

hyperinsulinaemic, euglycaemic clamp study, to demonstrate the

product’s hypoglycaemic response profile. Current EMA guidelines

for soluble insulin biosimilars do not require a clinical efficacy trial,

but do require a clinical safety study. The product’s immunogenicity

must be investigated through clinical studies of at least 12 months,

including a comparative phase lasting at least 6 months. Finally, the

manufacturer must also design a pharmacovigilance programme

that will rapidly detect any clinically significant immunogenicity

that may emerge over extended time periods.

21,28–30

The application

for marketing authorisation of three biosimilar insulin formulations

in March 2007 suggested deficiencies in long-term efficacy and

inadequate immunogenicity testing.

32–34

The details of these applications were recently reviewed by

Kuhlmann and Marre in this journal.

35

What clinicians should know before selecting a

biosimilar insulin

When contemplating biosimilar insulins, it is important to

consider the manufacturer, protein quality and formulation, batch

consistency and reliability of supply (Table 1).

36,37

Reassurance can

be gained from full disclosure of information to the healthcare

community about the manufacturing process and about safety

testing.

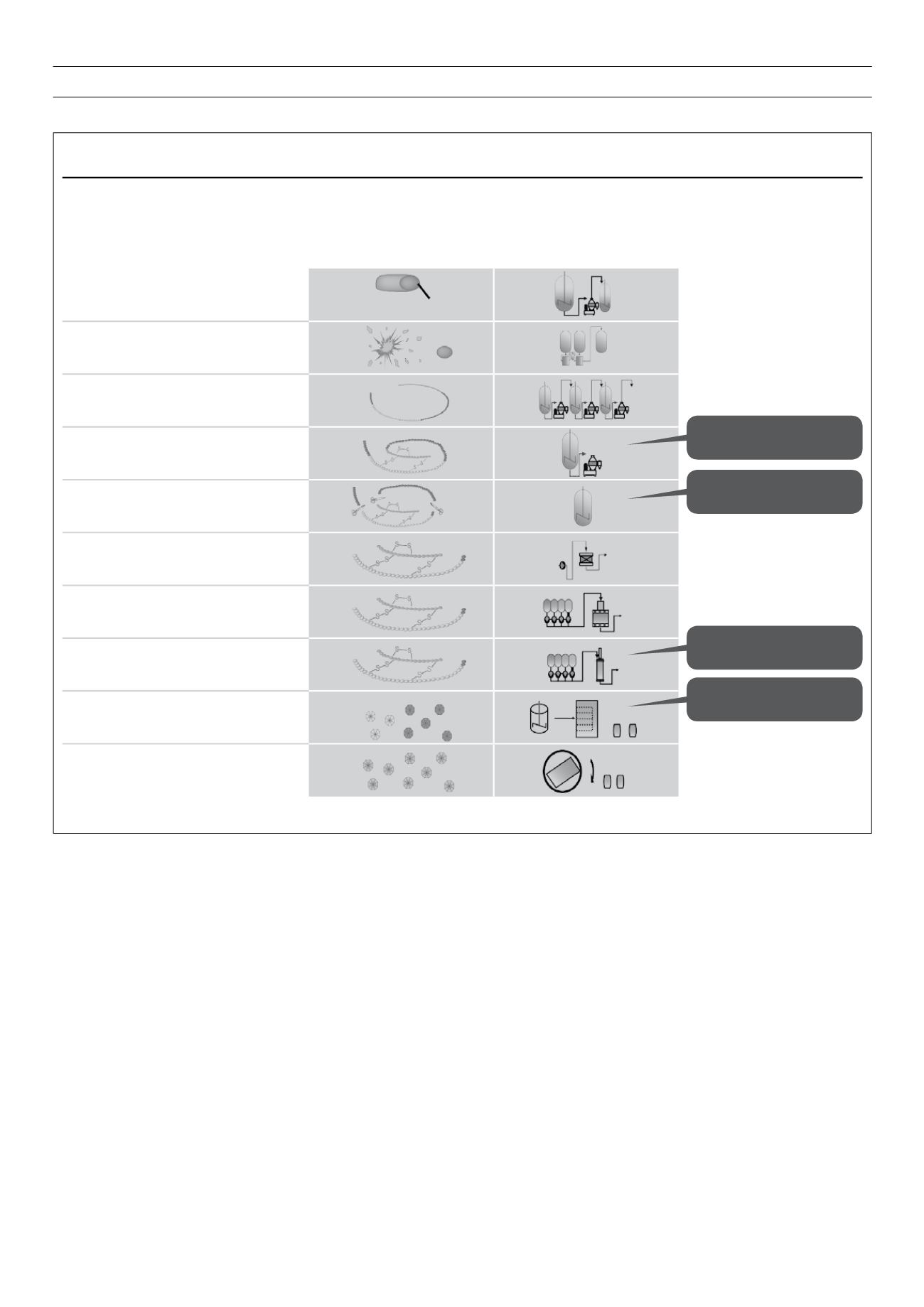

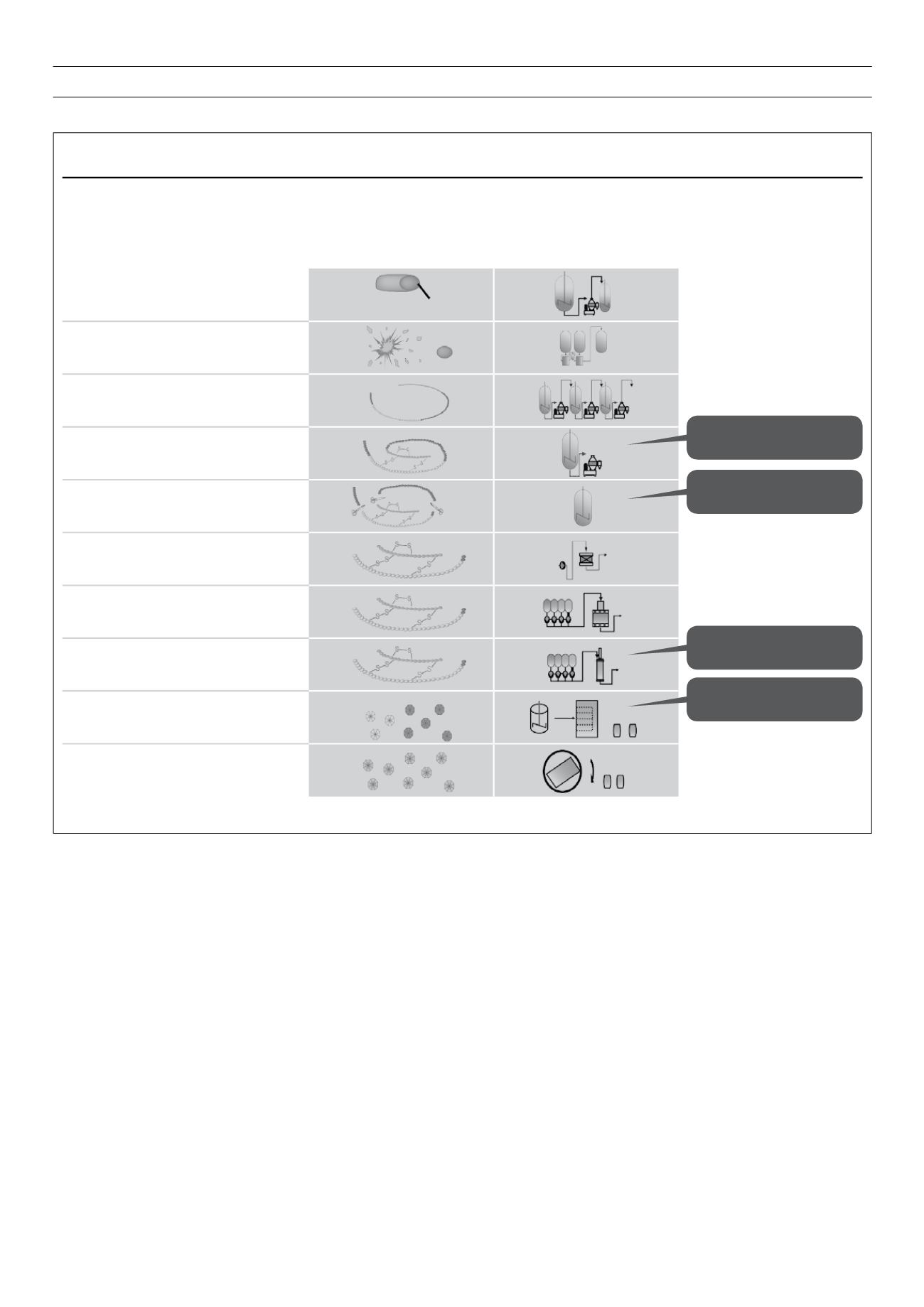

Figure 6.

A highly complex process: steps in the manufacture of insulin.

Reproduced with kind permission from sanofi-aventis group.

Insulin glargine:

Manufacturing is a complex, multi-step process

By-product profile influenced by folding and cleavage

Isolation of cells

Cell disruption via homogeniser

Isolation and Purification

Folding

Enzymatic cleavage

Prepurification and concentration via

absorption

Ion-exchange chromatography

Reversed-phase chromatography

Crystallisation and lyophilisation

Blending/filling

Typical operations

for inclusion

body processes

Folding conditions influence

by-product pattern

Cleavage enzyme:

specificity and selectivity

Chromatography defines

purity

Fibrillation tendency

E.coli

cell

Inclusion body

Fusion protein

Preproinsulin

Arg-Insulin

Insulin Glargine