REVIEW

SA JOURNAL OF DIABETES & VASCULAR DISEASE

20

VOLUME 8 NUMBER 1 • MARCH 2011

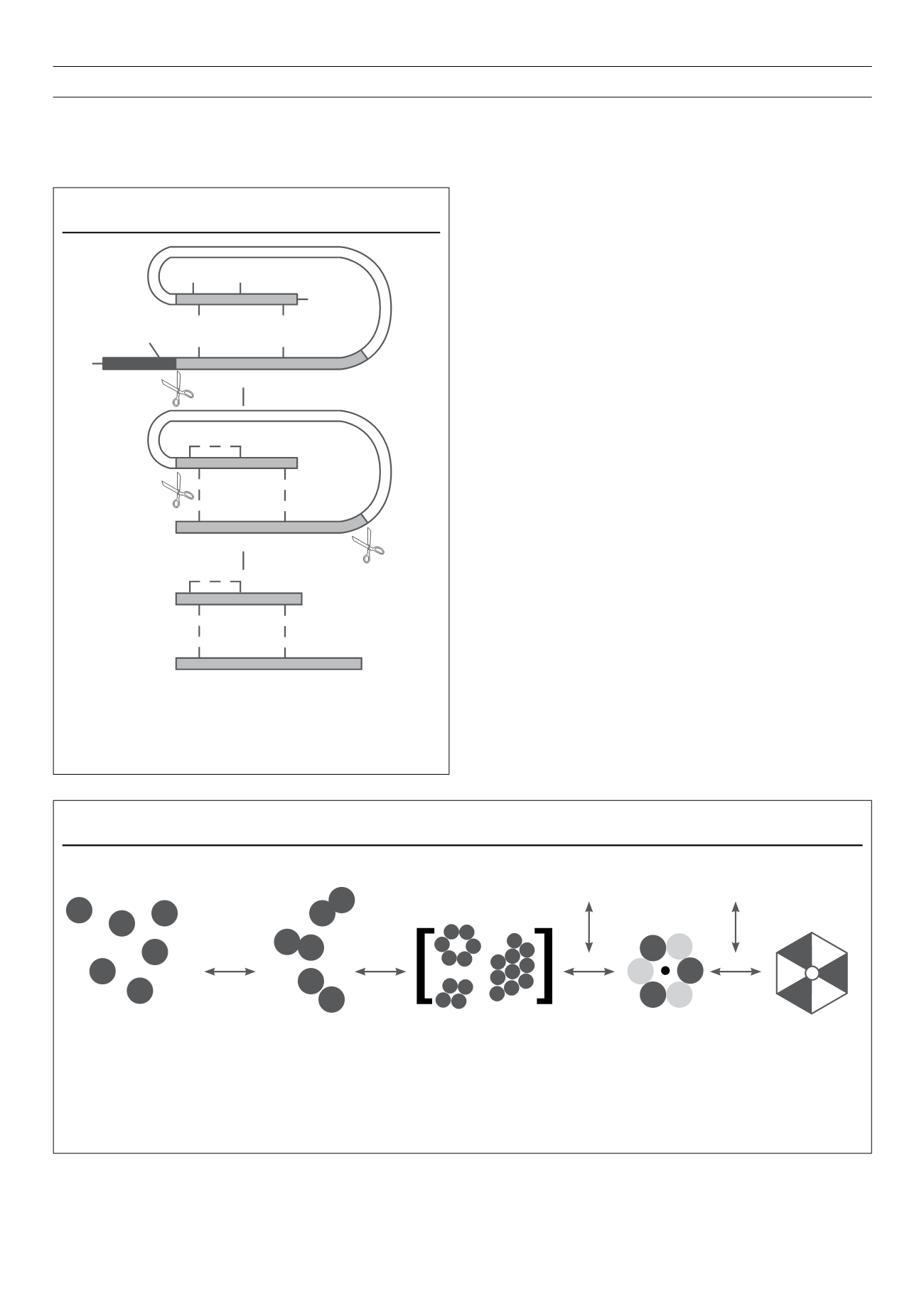

proteolytically cleaved to produce active insulin (Fig. 1). The insulin

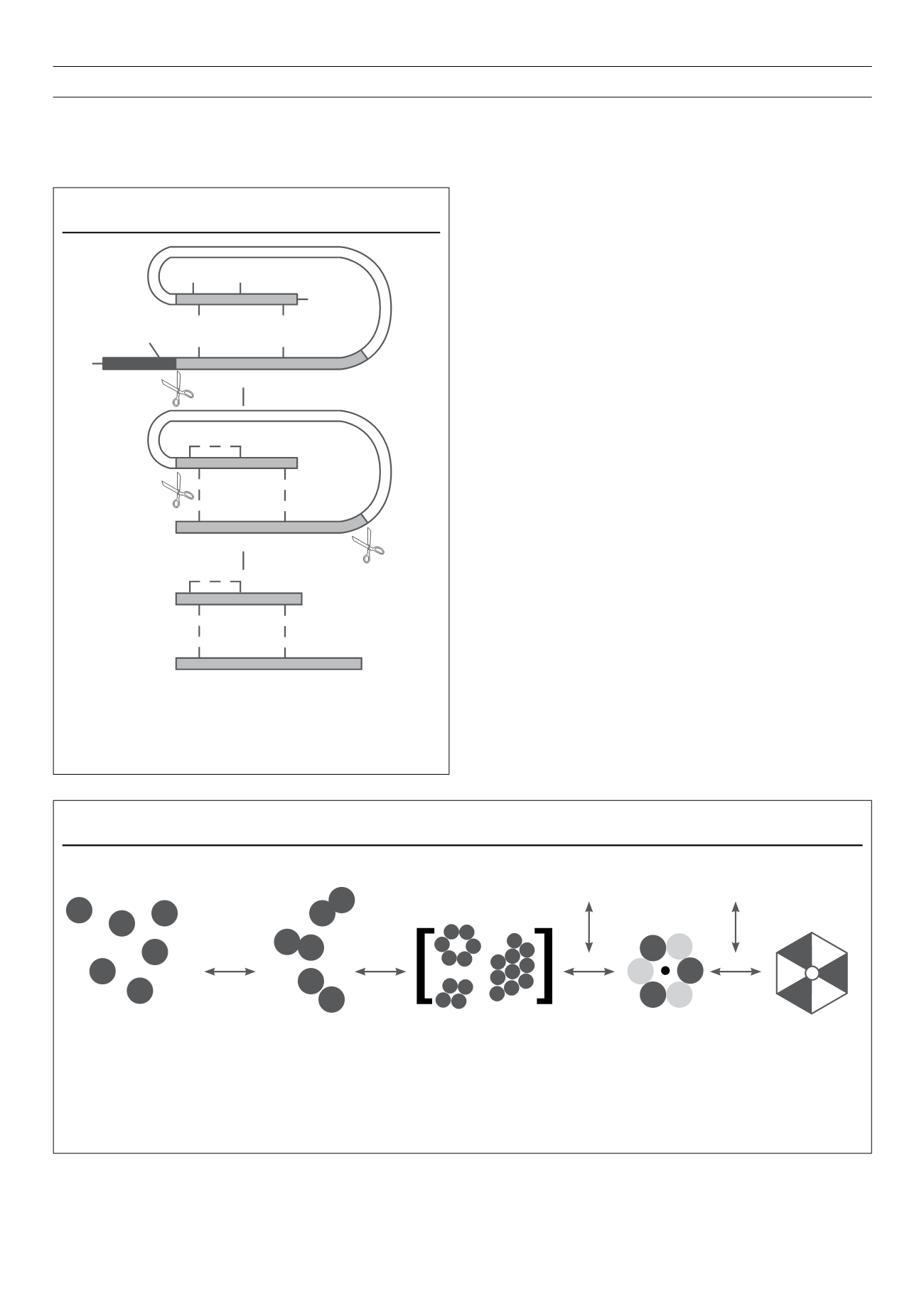

preparation must also be formulated to control the formation

of discrete hexamers (complexes of six insulin monomers), to

confer the required absorption characteristics (Fig. 2). The more

recent insulin analogues contain additional or substituted amino

acid residues or other functional groups introduced by genetic

engineering or by biochemical modification. These changes alter

the speed of bioavailability and thereby modify the PK and PD

profiles of the molecule.

Given their structural complexities biopharmaceuticals are

far more difficult to manufacture than small-molecule drugs.

The use of living organisms introduces an inherent variability

in the manufacturing process. To guarantee the quality and

compliance of each production batch, absolute consistency of the

manufacturing process is required. Even apparently slight changes

in any of the manufacturing or formulation steps can have major

clinical consequences.

4–8

Manufacturers of biosimilar products

must develop proprietary expression systems and processing steps

independently. Thus biopharmaceuticals can never be identical

copies of originator molecules, even when they have demonstrated

comparable physicochemical and biological properties to a

reference product using currently available tests. The most they can

achieve is ‘biosimilarity’.

5,9,10

For non-glycosylated products such as

human insulin, PK and PD differences are most probably caused

by differences in formulation, while for glycosylated products (e.g.

epoetin), the glycosylation pattern is probably the major source

of PK/PD variations. The essential steps in the manufacture of a

biopharmaceutical and the loci of potential variability in their

manufacturing processes are shown in Fig. 3.

11

The first commercial insulins, extracted from beef and pork

pancreata, became available shortly after the discovery of insulin

in 1921, and the first long-acting insulins, PZI and NPH, had been

developed by the 1940s. However, patients using animal insulin

products that were not highly purified often had local injection site

reactions or more rarely, systemic reactions such as IgE-mediated

anaphylaxis.

12

Highly purified products and recombinant insulins

are associated with decreased levels of anti-insulin antibodies.

Nonetheless, there is little evidence that antibody formation affects

glucose control or causes other complications of insulin therapy.

13

The more recent recombinant insulin analogues contain additional

Figure 1.

The biosynthesis of insulin.

The insulin precursor preproinsulin contains a signal sequence that is

proteolytically cleaved to yield proinsulin, whose C chain links the future A

and B chains of mature insulin. Cleavage of the C chain converts proinsulin

to insulin.

Adapted from Joshi SR,

et al

.

J Assoc Physicians India

2007;

55

(suppl): 19–25.

14

C-Peptide

SH SH

SH

SH

SH

SH

COO –

Signal sequence

Preproinsulin

H

3

N

Signal peptidase

cleavage

Tryptic

cleavage

A Chain

B Chain

C-Peptide

S S

S

A Chain

B Chain

Proinsulin

S

S S

Tryptic

cleavage

S S

S

A Chain

B Chain

Insulin

S

S S

Figure 2.

Association of insulin monomers in the presence and absence of zinc and phenolic excipients.

Insulin readily associates into dimers, aggregates and (in the presence of divalent cations such as zinc), into hexameric forms. The presence of phenolic excipients

causes these hexamers to undergo conformational changes that increase their stability.

R6

=

hexamer with insulin molecules whose B1–B8 residues are in an

α

-helical (R) conformation; T6

=

hexamer with insulin molecules whose B1–B8 resi-dues are

in an extended (T) conformation.

Adapted from Beals,

et al

. Informa Healthcare: New York, 2008; 265–80.

22

Insulin

monomer

Insulin

dimer

Insulin

aggregates

Insulin

hexamer (T6)

Insulin

hexamer (R6)

Phenolic

preservative

Zn

2+